Students at ETH Zurich Invent Rotary Metal 3D Printer

It may make space travel cheaper

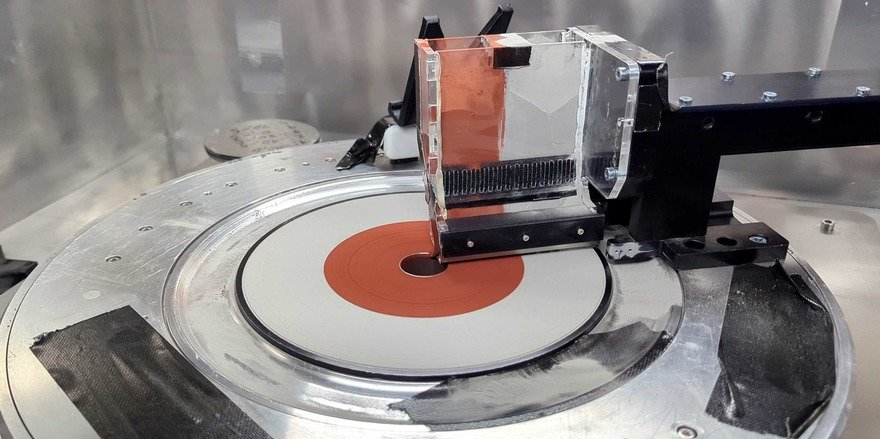

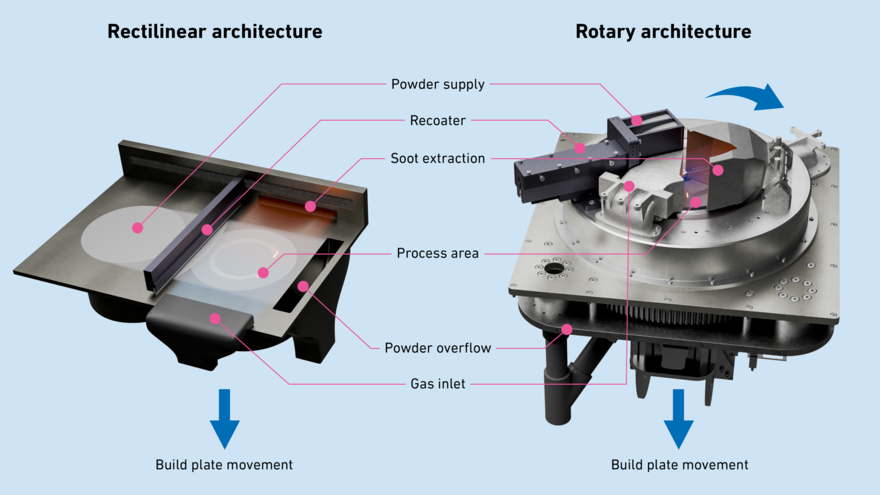

Students at ETH Zurich have invented a new type of metal 3D printer, which takes a cue from turntables: It spins. Designed specifically to produce cylindrical objects, it reduces manufacturing time versus conventional laser powder bed fusion machines (LPBF) by a staggering two-thirds.

Image: Michael Tucker / ETH Zurich

Image: Michael Tucker / ETH Zurich

Image: Michael Tucker / ETH Zurich

Image: Michael Tucker / ETH Zurich

With conventional LPBF machines, a layer of powder is spread, then the laser takes a pass, fusing select parts of the layer. Then another layer of powder is spread, and so on. With ETH's Rapture machine, however, the powder is spread and the laser is fusing continuously, with no dead time between layers.

Enter a caption (optional)

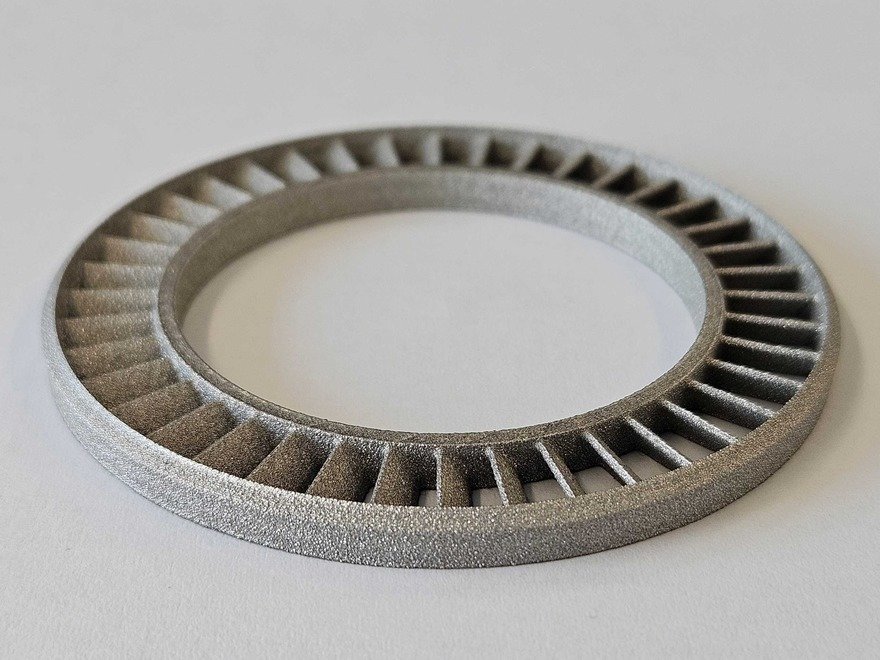

The Rapture can also handle two different metals at once and lay the particles with precision, greatly reducing waste.

"This process is ideally suited to rocket nozzles, rotating engines and many other components in the aerospace industry," says ETH Senior Scientist Michael Tucker. "They typically have a large diameter but very thin walls."

Image: Michael Tucker / ETH Zurich

Image: Michael Tucker / ETH Zurich

The project was supported by ARIS, the Swiss Academic Space Initiative, which plans to build its own rockets. Rapture could make that an affordable reality.

-

o1Favorite This

-

QComment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.