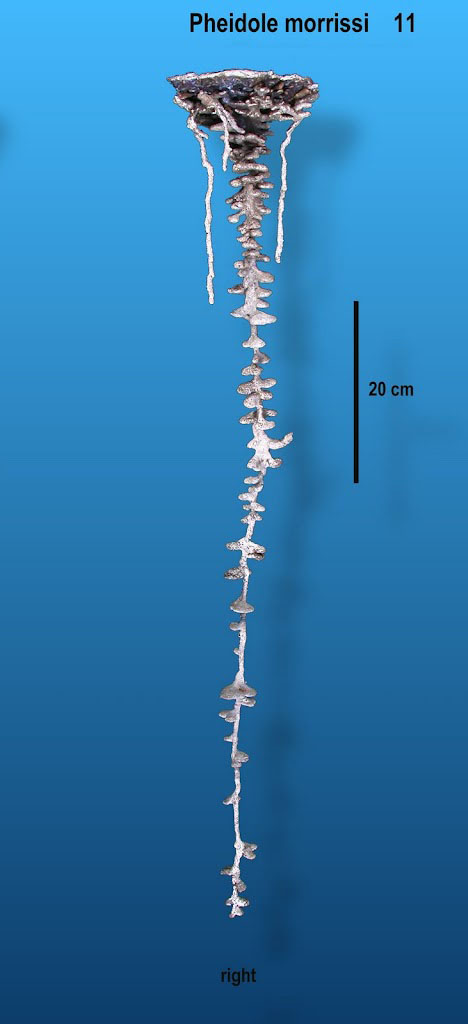

Walter Tschinkel's Aluminum Casts of Ant Colonies Reveals Insect Architecture

Portrait by Mark Wallheiser

Portrait by Mark WallheiserThis is pretty freaking amazing, and gives new meaning to the term "sacrifical casting." Retiree Walter R. Tschinkel is an entomologist and former professor of Biological Science at Florida State University. He recognizes ants as "some of nature's grand architects" and, curious to understand their self-created habitats, devised a clever (if cruel) way to do it: By pouring molten aluminum down into the hole.

Unsurprisingly, the ants die in the process. But after the aluminum cools and Tschinkel has completed a meticulous excavation, he unearths these wondrous, chandelier-esque shapes revealing the alien architectures of the colony.

Tschinkel has discovered that colonies can be up to twelve feet deep and house between 9,000 and 10,000 workers.

If you're wondering how he can tell how many ants were in there, he started doing this in the '80s by making plaster casts, which did not vaporize the ants. By breaking apart the plaster, he could count the little buggers. (BONUS: Watch the Video of the Process after the jump)

So why the switch from plaster to aluminum? For the same reason manufacturers will make car parts out of one but not the other. "The disadvantage of plaster casts is that they break easily so after you dig them up, you have to glue the pieces back together again," Tschinkel said in a 2008 interview. The aluminum has proven more robust.

In addition to aluminum, he also uses zinc "for its low melting point," and harvests both materials from old objects.

I get the zinc free from old anodes at marine shipyards. Zinc corrodes and steel doesn't, so they attach zinc bars to the hull of the ship, and replace them when they are about half corroded away. Sometimes I use aluminum from old aluminum scuba tanks. We place charcoal in an insulated garbage can, and put the aluminum in the bottom half of a steel scuba tank to melt metal [placed in a smaller container within the tank and then pour the molten metal down the nest opening].

Here's a video showing the process:

via doobybrain

-

oFavorite This

-

Q33Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

Many international manufacturing companies order the Aluminium Castings in India because it's cost effective to buy from India. The Aluminium Casting Process in India is very inexpensive compared to that in Middle East Nations, Asian Countries and European countries. Dwarkesh Industries Aluminium Casting in India www.dwarkeshindustries.in

He's not being "cruel" to repeat this with different colonies, he's doing good science - and he's working with a creature that has almost no brain whatsoever. He's certainly not doing anything to bring down the vast number of ants that surround us at all times, nor is he 'torturing' anything. I think being surrounded by molten aluminum is probably about the quickest death I could think of for a critter that size - poison would take far, far longer, and would probably cause far more distress, whatever 'distress' an ant can feel as it begins to fail.

Did you wash your hands this morning and kill billions of bacteria? Brush your teeth and kill billions of bacteria? Cut the grass and got the blood of innocents staining your shoes?

Did you not sever the ovaries of plants and throw them in a blender so you could make a healthy fruit smoothie? Didn't tear off the limbs of plants for your salad? How many bugs died in the plants you consumed?

Oh, what's that? Bacteria and plants and pests don't count as life forms because they're not cuddly, cute, or curious and it would contradict your twisted personal worldview which you judge the world by (a world which runs on established law and not your worldview)? Keep telling yourself that so you can pretend to be better than other people.

Mother nature doesn't care about you. Mother nature hates your guts. Mother nature will kill you every chance it gets with everything it has. There is no crueler force than mother nature, killing off trillions of living things and wiping phylums and classes and orders and families and genus and species off the face of the planet for billions of years.

Thank you Frank, after hearing all the intense discussion about the preservation of 'all' life, (and veganism) you have expressed my thoughts perfectly.

One of the most idiotic comment here - "Ants don't feel pain"

Cruel? Yes. But hey, eating meat is cruel too, but the entire world does it and it's universally accepted. I don't see people slamming pest-busters either.

Science has to be done. Without it, most of us would probably not even be alive to debate about retarded things like whether this guy is "sick". (cus most of our ancestors would have died from famines)

Then again, this world might be better off without science cus we'd be too busy running away from lions to have retarded debates about inconsequential things. In particular, I'd thoroughly enjoy the sight of his critics running away from lions. You can label me as "sick", but at least I'm not a hypocrite.

2. Seriously, if you want to complain about killing ants, go protest raid.

3. Just stop trolling, you're making yourself look retarded.

Are you vegan, or at least vegetarian? Do you wear leather shoes or have leather in your car? Do you spay and neuter your pets to reduce the number of unwanted and euthanized cats and dogs?

He's doing this FOR SCIENCE. Ant behavior, etc. Just because you don't know anything about it doesn't mean someone else doesn't want to, or that it's not worth knowing anything about.

Then there's the problem of receiving/transmitting the GPS signal. Have you ever tried using your cellphone inside a tunnel? No signal? GPS works the same way, except you need to be able to receive a signal from SPACE. That might get through the first inch of dirt, and that's about it.

I've probably killed more any colonies in my backyard than this guy has in the name of science.

http://www.youtube.com/watch?v=f0qdJh0YEAI&list=UUpIGFcvUqnoUALWXqmQ6YnA

This is the most detailed model of such a mound ever made. Turner also has some clear ideas about how termites control the temperature and humidity in their mounds, knowledge that can help make buildings more comfortable and energy efficient.