By leveraging 5-axis CNC machining, automotive components are manufactured with unmatched precision, which enhances their performance and significantly accelerates the product development cycle. This advanced technology is capable of producing a wide array of critical metal parts, including but not limited to:

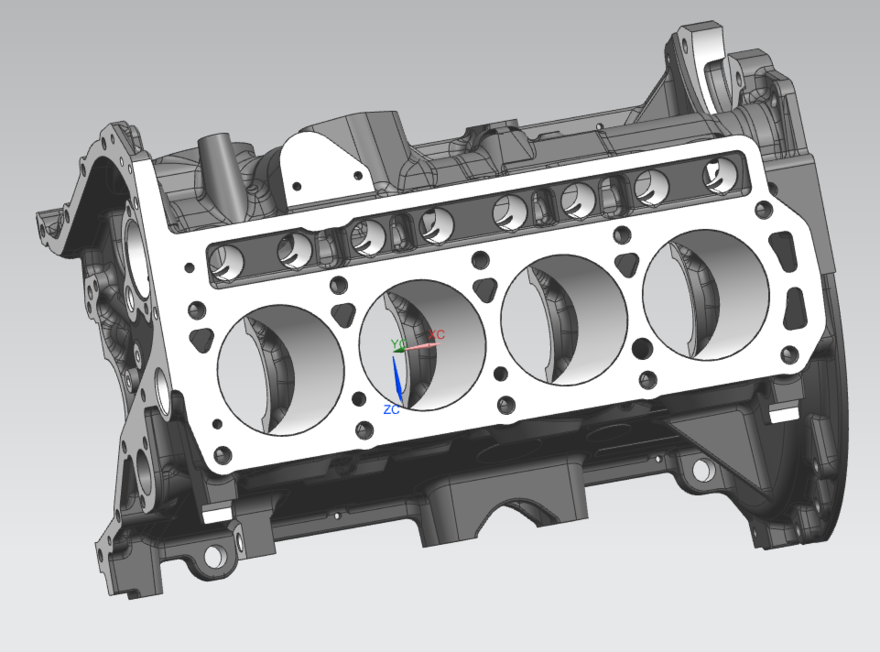

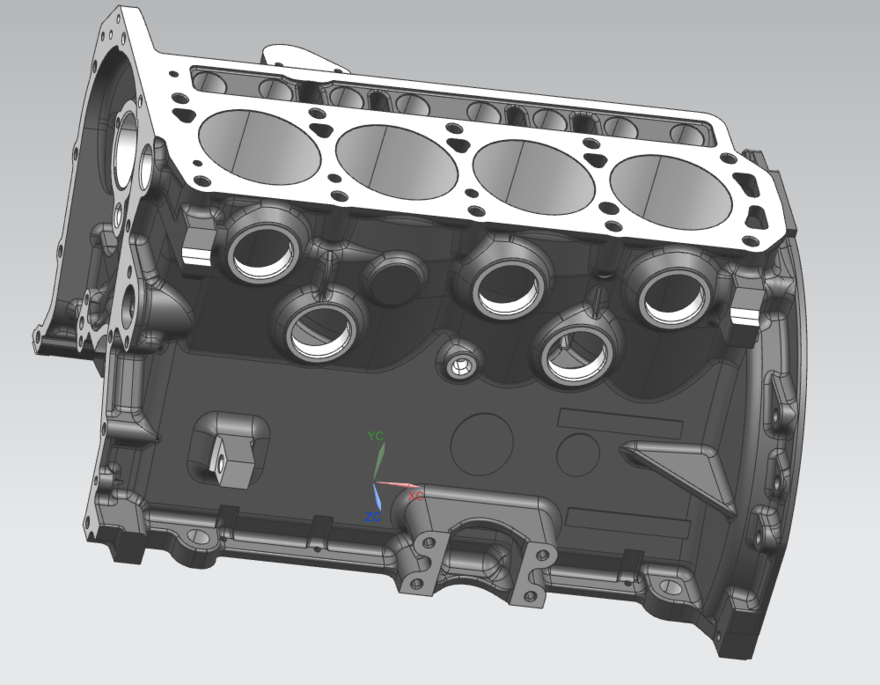

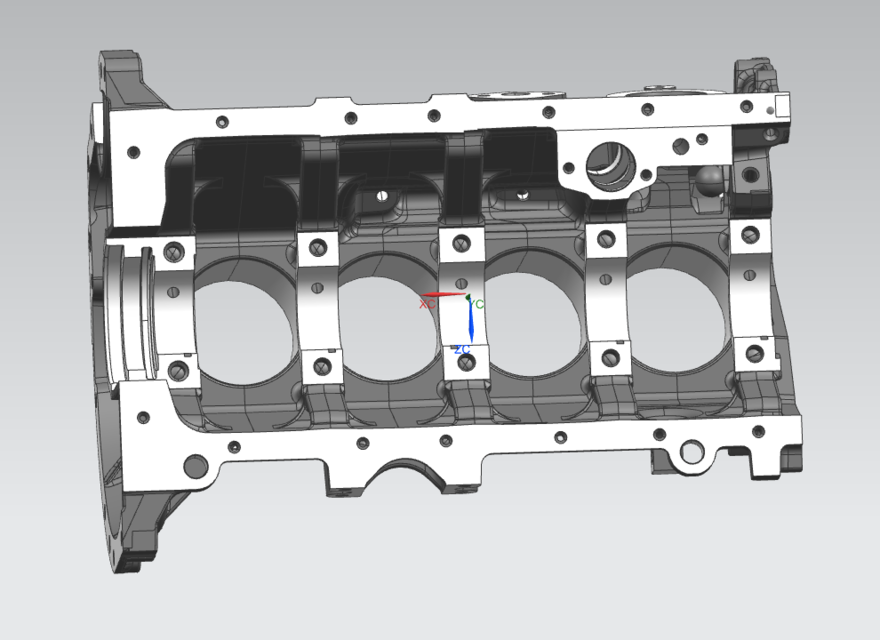

Engine Components: Cylinder heads, engine blocks, connecting rods, and turbocharger housings.

Transmission Systems: Gearbox casings, drive shafts, differential carriers, and complex gear sets.

Chassis and Suspension: Steering knuckles, control arms, brake calipers, and suspension mounts.

Wheels and Hubs: Custom alloy wheels and wheel hubs.

Body and Interior: Lightweight structural frames, intricate door handles, and customized dashboard elements.

The ability to complete these complex geometries in a single setup not only eliminates the cumulative errors associated with repositioning parts across multiple machines but also drastically reduces production lead times. Furthermore, the superior surface finish and tighter tolerances achieved directly contribute to improved engine efficiency, vehicle durability, and overall safety. Consequently, manufacturers can iterate prototypes with unprecedented speed, compress time-to-market for new models, and ultimately produce higher-performing, more reliable vehicles.