When a leading medical device manufacturer approached us with a critical challenge—producing ultra-high-precision aluminum alloy components with tolerances as tight as ±0.01mm—we knew it would push our capabilities to the limit.

The client required intricate, medical-grade aluminum parts for a next-generation surgical instrument. Any deviation beyond 0.01mm could compromise performance, making conventional machining methods insufficient.

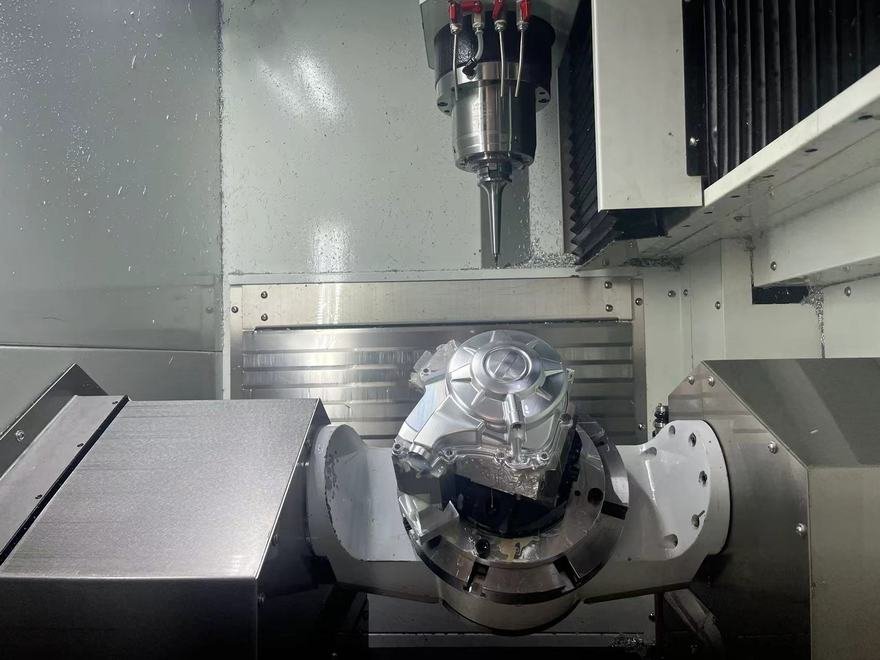

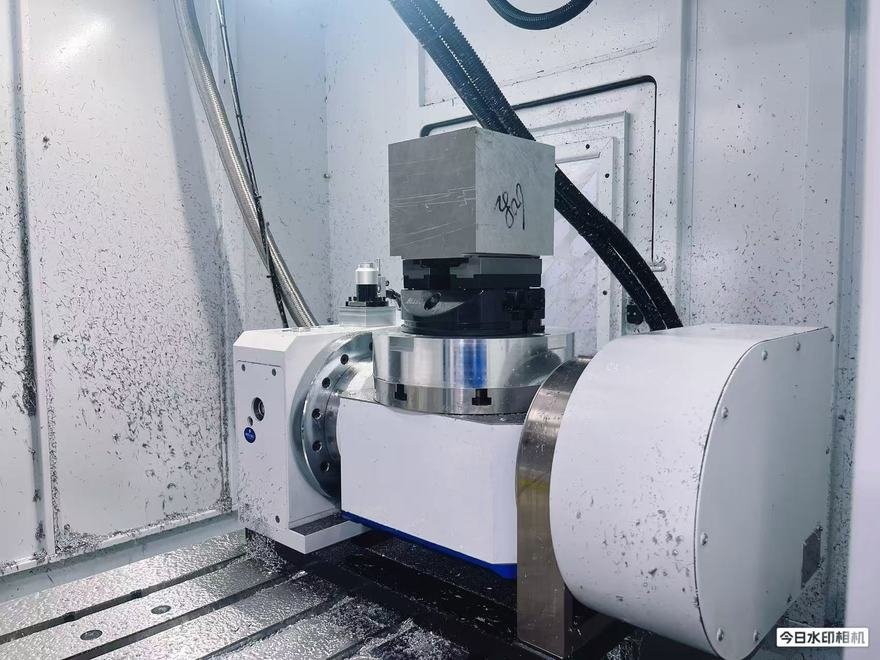

Leveraging our 5-axis CNC machining expertise, we achieved near-perfect geometric accuracy. For the most complex internal features, we complemented CNC with precision EDM (Electrical Discharge Machining) to ensure flawless surface finishes and dimensional stability.

Unmatched Precision: Final parts met the ±0.01mm tolerance requirement consistently.

Medical-Grade Quality: Burr-free edges and ultra-smooth surfaces met stringent ISO 13485 standards.

Client Satisfaction: The customer was thrilled with the results, confirming the parts integrated seamlessly into their assembly.

*"Your team's expertise in 5-axis CNC and EDM made the impossible possible. These components are perfect."* — Client Feedback

By combining advanced machining technologies with rigorous quality control, we delivered precision that heals.