e

Design Business

+ Follow this feed-

Fantastic Industrial Design Case Study: Creating a Custom Orthotic, Fast, with Formlabs

Here's a great piece of design, executed in a hurry. Unfortunately the designer never...

September 16

-

Industrial Design Case Study: A Nurse Call System for Hospitals

The Voalte Nurse Call Station, designed by Thrive

September 12

2 Comments -

Industrial Design Case Study: A Magic Handheld X-Ray Machine for Law Enforcement

The Viken Raven, by Sprout Studios

September 5

3 Comments -

Industrial Design Case Study: An Automated Robot Parking System

By Mighty Studios and Volley Automation

August 29

3 Comments -

The Best Way to Address Product Design Failure

Peak Design shows how to make things right

August 28

2 Comments 6 Favorites -

Design Impact Scholarship Offered for MBA Equivalent for Designers

Future London Academy's Executive Programme for Design Leaders

August 28

-

Industrial Design Case Study: A Designey Concrete Firepit with Improved Manufacturability

Sunflower, designed by Shift Studio

August 22

7 Favorites -

-

Designey Doormats, Borne From an Industrial Laundry in Norway

Heymat provides industrial performance with Scandinavian looks

August 21

1 Comment -

Industrial Design Case Study: Designing NFL-Level Shoulder Pads

Studio RedEye's X2 model for XTECH

August 15

1 Comment -

Choo Choo the Seahorse: When Industrial Design Meets Baby Products

Scott Henderson's Integrated Approach Creates a Product Ecosystem

August 14

-

Industrial Design Case Study: An Experimental "Café Classroom"

Pearson Lloyd explores future-facing learning spaces

August 8

-

Product Design Student's Self-Project Leads to Massive Business Success

Angus Willows designs a better coat hanger

July 30

7 Favorites -

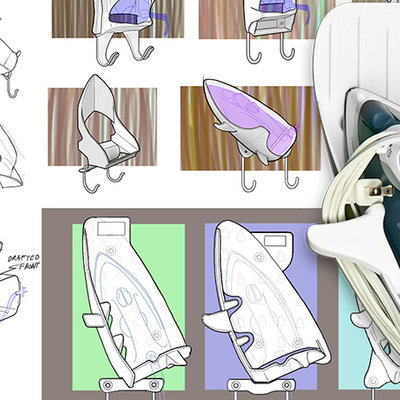

Industrial Design Case Study: A Steam Iron Organizer

By ID consultancy The Metcalfe Group

July 25

1 Comment -

The iF Design Academy Seeks to Teach Design Leadership Skills

For veteran designers looking to get to the next level, iF Design has announced...

July 23

-

American Solution for Burning EVs: A Modular, Portable Submersion Pool

A flood-control company spies a new opportunity

July 21

2 Comments -

Industrial Design Case Study: Customizable 3D-Printed Lamps

The Dollight, by Official Use Only, spawns a new company

July 18

2 Comments -

UX Design Case Study: Designworks Improves Urban Mobility in Los Angeles

This Friday we've got something special: A UX design case study, of which we...

July 11

1 Comment -

-

Furniture Design Case Study: Making the Table for the G7 Summit

Teknion creates a massive showpiece for diplomacy

July 3

6 Favorites -

Industrial Design Case Study: Prime Studio's Flagship Razor for Dorco

This ID case study comes to us from NYC-based Prime Studio. DORCO, the leading...

June 20

7 Favorites -

Industrial Design Case Study: Industrial Kitchen Equipment

Curve ID designs the JAVAR Meatgrinder

June 13

-

Industrial Design Case Study: A Laptop Privacy Shield

The Alcove Workstation, by Y Studios

June 6

1 Comment -

Industrial Design Case Study: PDR Brings Dignity to Catheter Bags

This Shield concept is by PDR, an industrial design consultancy based in Cardiff, Wales....

May 30

5 Favorites -

Industrial Design Case Study: Fluid Design Updates Beurer's Grooming Devices

Beurer is a German manufacturer of personal care products. When they needed to update...

May 23

-

Industrial Design Case Study: Tactile Helps Milwaukee Perfect Their Digital Level

Integrating digital tech into a tried-and-true analog tool requires careful thought, rather than just...

May 16

1 Comment -

Automatic Photo Timestamp/Location-Stamp Apps for Keeping Track of Projects

What industrial designers, architects and contractors have in common: They all do client work...

May 13

-

Industrial Design Case Study: A Lightweight, Inflatable Travel Kennel

The Diggs Eventur, by ID firm Pensa

May 9

-

Industrial Design Case Study: Dremel's Next Generation Power Tools

Sundberg Ferar helps the brand evolve

May 2

1 Comment -

Industrial Design Case Study: A Communications Analyzer

Mixer Design tackles radio testing equipment

April 25

1 Comment -

Industrial Design Insights: Whipsaw on Using AI for Digital Product Prototyping

"For all of the designers out there, or people who have been privy to...

April 18

1 Comment -

Industrial Design Case Study: A Mobile Airport Lounge

The Dovetail concept, by Formation Design Group

April 11

4 Comments -

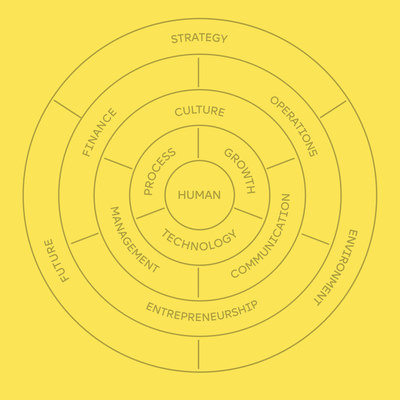

Unlocking Innovation with Psycho-Aesthetics 2.0

Focus on the human experience to inspire long-term engagement and loyalty in the products and services you create

March 31

2 Comments

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.