e

Digital Fabrication

+ Follow this feed-

Fantastic Industrial Design Case Study: Creating a Custom Orthotic, Fast, with Formlabs

Here's a great piece of design, executed in a hurry. Unfortunately the designer never...

September 16

-

-

-

Sponsored Post

From Imperfection to Innovation: How Digital Materials Support Sustainable Design

A conversation with Nicolas Paulhac, Director of 3D Content at Adobe Substance

September 9

-

-

An Innovative Rail-Based Wall-Mounted Planter System

Designed by Brian Hendricks, a/k/a Lofted Goods

August 29

-

In Texas, 3D Printed Homes Inch Closer to Being Affordable

Icon gets an assist from the Mueller Foundation

August 13

3 Comments -

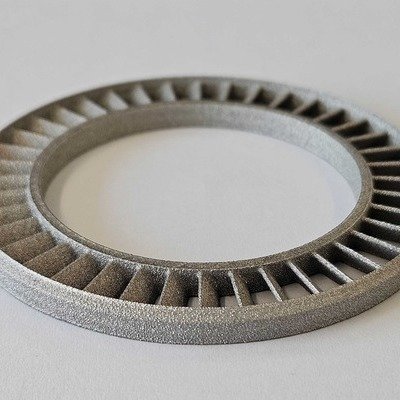

How 3D Printing Will Lead to Cheaper Energy

A surprisingly agile government lab has made a breakthrough

August 6

1 Comment -

Industrial Design Case Study: Customizable 3D-Printed Lamps

The Dollight, by Official Use Only, spawns a new company

July 18

2 Comments -

Adidas Launches 3D-Printed Climacool Laced Sneakers

Today Adidas releases their 3D-printed Climacool Laced sneakers. Last year they released a similar...

July 15

-

Peter Donder's Mysterious and Beautiful Robotic Chicken Feet

Peter Donders, the Belgian designer who routinely harnesses industrial processes to create objects that...

June 5

-

Far Cheaper, Pellet-Based Industrial 3D Printing

Feedstock for the PAM is 5 to10 times less expensive than filament

June 5

2 Comments -

Marc 3DP's Love Letter to 3D-Printed Fidget Toys

This Fidgets 2.0 project is by YouTuber and 3D printing enthusiast Marc 3DP. He...

May 27

-

Philips to Offer Free Downloadable Files to 3D Print Replacement Parts

Their Fixables program is in its infancy

May 20

-

The Spherene Side Table, by Peter Donders

The Belgian designer stretches material optimization to extremes

May 6

3 Comments -

-

The Rotary-Printed HIVE Lamp, by Stijn van Aardenne

Earlier this year, we watched in fascination as Dutch designer Stijn van Aardenne developed...

April 22

1 Comment -

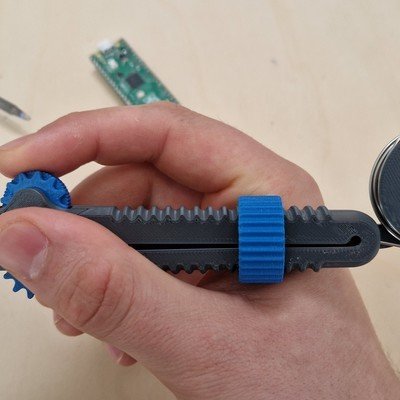

Clever Design for an Easy-to-Use 3D-Printed Solder Dispenser

The Solder Scroll, by Victor Designs

April 21

1 Comment -

Modern-Day Autoprogettazione: The Delta Lamp

By industrial designer Christoph Hauf and 1x1 Systems

March 3

-

3D Printing on a Bed That Can Tilt and Move Yields Unique Objects

The Honey Dipper, by Dutch designer Stijn van Aardenne

February 14

-

A Portable CNC Mill for Concrete and Stone Applications

The CNC Pro, by Red Art technologies

January 30

3 Comments -

LMD: A New, Less Wasteful Metal 3D Printing Technique

Meltio's Wire-Laser Metal Deposition

January 28

2 Comments -

Icon to 3D Print Houses for the Homeless

The Community First! Village is tackling Austin's homeless population

January 16

4 Comments -

Tomorrow: Tune In to Formlabs 3D Printing User Conference

Covering how 3D printing is impacting various industries

November 12, 2024

-

Ross Lovegrove's 3D-Printed Door Handles

Done in collaboration with JNF Architectural Hardware

October 21, 2024

9 Comments -

Sponsored Post

84% of U.S. Manufacturers Anticipate a Recession in Next Two Years

Manufacturing leaders are under pressure, with the economy, talent challenges and digital transformation at the forefront of leader's minds.

October 10, 2024

-

Making a Silicone Bag Using Rapid Liquid Printing

French fashion brand Coperni's Swipe Bag is one of their distinctive offerings. For an...

October 9, 2024

-

-

Sustainable 3D-Printed Glass Masonry

MIT engineers produce fully recyclable interlocking glass bricks

September 23, 2024

3 Comments -

New Production Method: Impact Printing

ETH Zurich's clay-based "high velocity deposition"

September 23, 2024

2 Comments -

-

New Production Method: Digital Sheet Forming

Form sheet metal without presses, tools and dies

September 5, 2024

11 Comments -

Lightweight, Beautiful 3D-Printed Camper Van Interiors

Easy on the eyes, saves on gas

August 28, 2024

1 Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.